Battery packs are not interchangeable commodities. They are critical systems that determine whether industrial equipment operates efficiently and whether defense missions succeed in the field. The wrong pack choice can mean forklifts that cannot complete a shift, drones that lose power mid-mission, or vehicles sidelined due to overheating. For organizations where downtime equates to lost revenue or compromised safety, the stakes are too high to leave battery selection to chance.

Industrial and defense programs face unique challenges that consumer applications do not. Equipment must withstand extreme environments, deliver consistent performance under heavy loads, and comply with rigorous safety and regulatory standards. At the same time, program timelines are shrinking. Manufacturers and defense contractors are expected to move faster than ever before without sacrificing reliability.

Too often, companies approach battery selection by relying solely on datasheets or off-the-shelf solutions. While convenient, this approach rarely accounts for the realities of field use. The result is expensive redesigns, supply chain setbacks, and compromised mission performance.

The alternative is a structured decision-making framework that connects mission requirements directly to pack design, risk management, and validation. In this article, we outline a practical five-step process that helps industrial and defense organizations choose the right battery pack the first time. The result is reduced risk, faster deployment, and more reliable long-term performance.

The most effective way to begin the battery selection process is by defining the mission first. A battery pack should always be engineered to serve the specific operational goals of the system it powers, not chosen from a specification sheet in isolation. Starting with the mission ensures that every design decision is tied directly to real-world performance and program success.

For example:

Starting with the mission ensures that design trade-offs are made with the end goal in mind. Without this step, teams often over-engineer packs that are technically impressive but operationally impractical.

Action: Before evaluating chemistries or pack formats, create a one-page mission profile. This should define:

This document becomes the foundation for every decision that follows. It forces clarity, aligns stakeholders, and provides a benchmark to evaluate potential designs. In practice, it often eliminates solutions that look good on paper but would fail in the field.

Once the mission profile is clear, the next step is to convert those operational goals into measurable energy and power requirements. This is where many projects run into trouble. Teams often calculate only the total energy capacity they think they need, then discover later that the pack cannot deliver peak power when required, or that the design is too bulky to fit the system.

A strong evaluation looks at both energy (how long the pack can run) and power (how quickly it can deliver that energy). For example:

Design teams must also account for trade-offs. High energy density often comes at the expense of ruggedness or safety margins. Packs built for high power output may sacrifice cycle life. The challenge is not simply maximizing one attribute, but balancing all three to meet the mission profile.

Action: Build a simple “mission map” that lays out your power and energy needs across different operating scenarios. This should include:

Overlaying these scenarios helps identify the gaps where off-the-shelf packs are likely to fail. It also informs the right questions to ask a battery partner, such as whether modular packs can be scaled up for longer missions or configured to deliver higher bursts of power when required.

By translating mission goals into detailed power requirements, organizations avoid the costly mistake of designing around average values that do not reflect real-world usage. The result is a battery pack that matches the mission instead of forcing the mission to adapt to the pack.

Every battery program carries risk. It might be technical, regulatory, or supply chain related, but it is always present. The mistake many organizations make is leaving risk evaluation until late in the design process. By then, design changes are costly, supply options are limited, and deadlines are already under pressure. The better approach is to map and prioritize risks before the design is finalized so that mitigation strategies can be built into the plan from the start.

Common risk areas include:

Action: Build a “risk register” as soon as the mission profile and preliminary requirements are defined. This document should:

A well-maintained risk register becomes a living tool that guides both design decisions and program management. For example, if thermal risks rank highest, more investment can be directed toward advanced cooling systems or cell selection. If supply chain risks dominate, sourcing strategies can be adjusted before final design lock.

By addressing risks early, organizations avoid surprises that cause six-month delays or budget overruns. More importantly, they create a battery pack that is resilient not just in the lab, but in the unpredictable conditions of the real world.

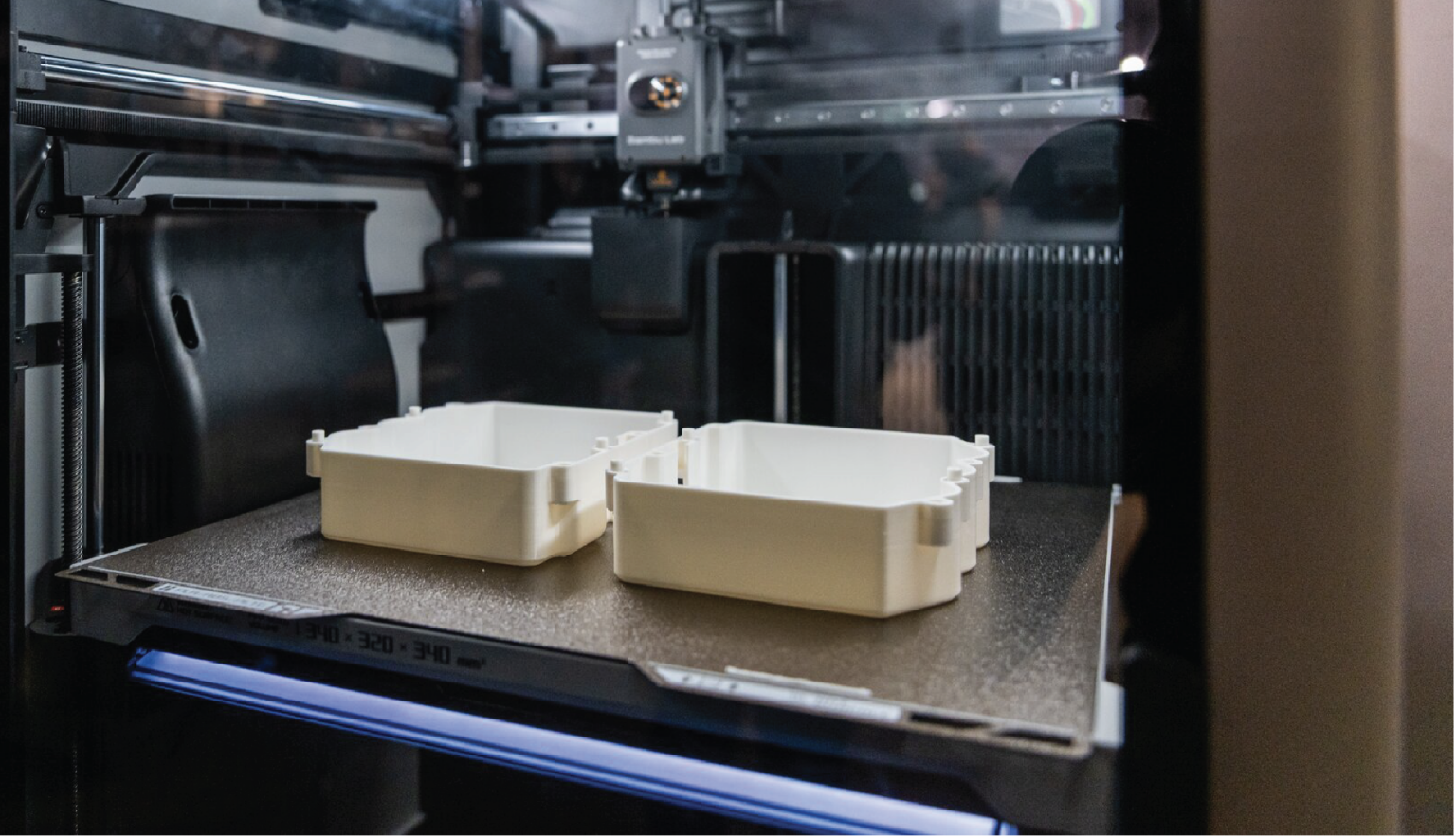

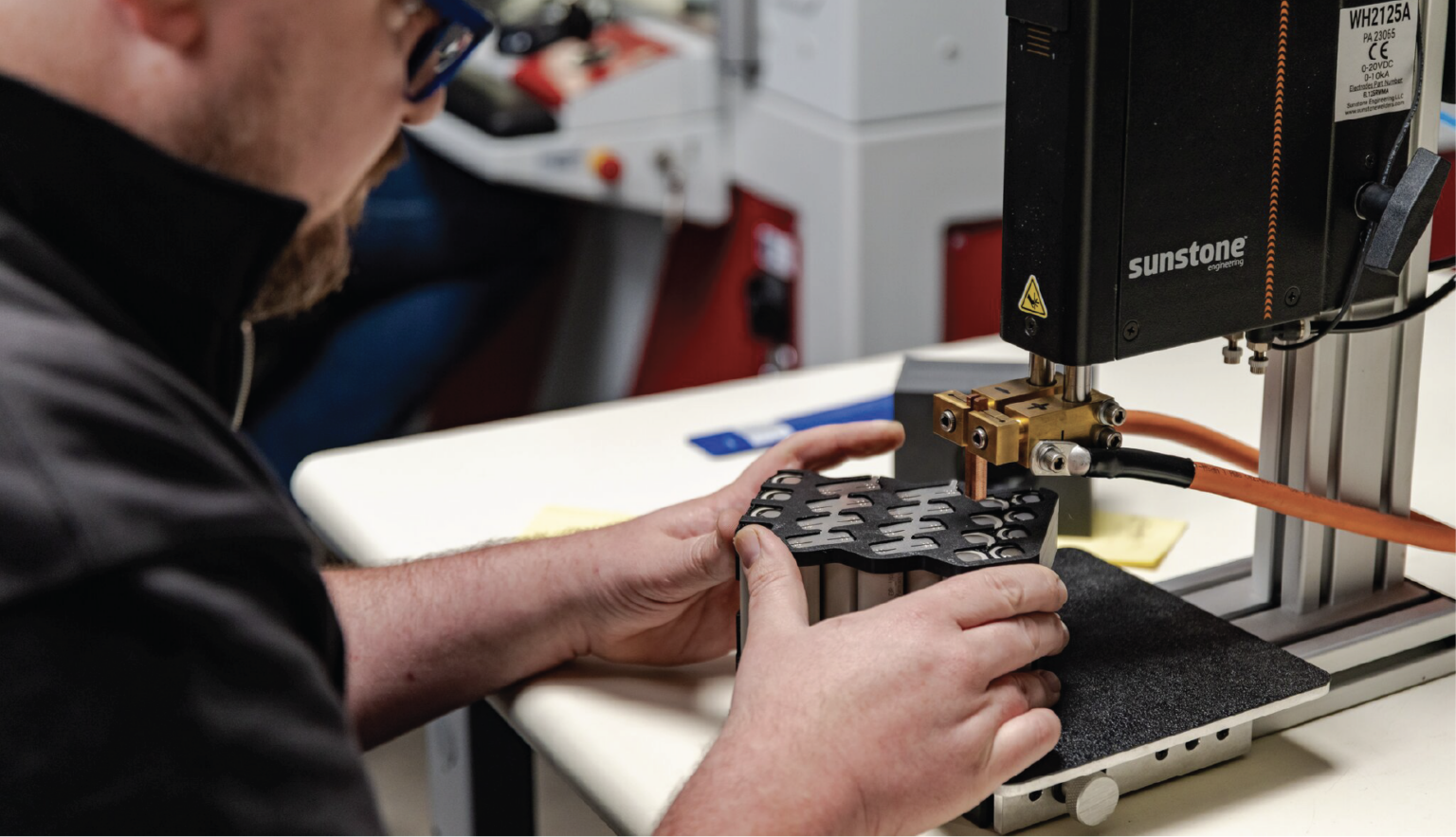

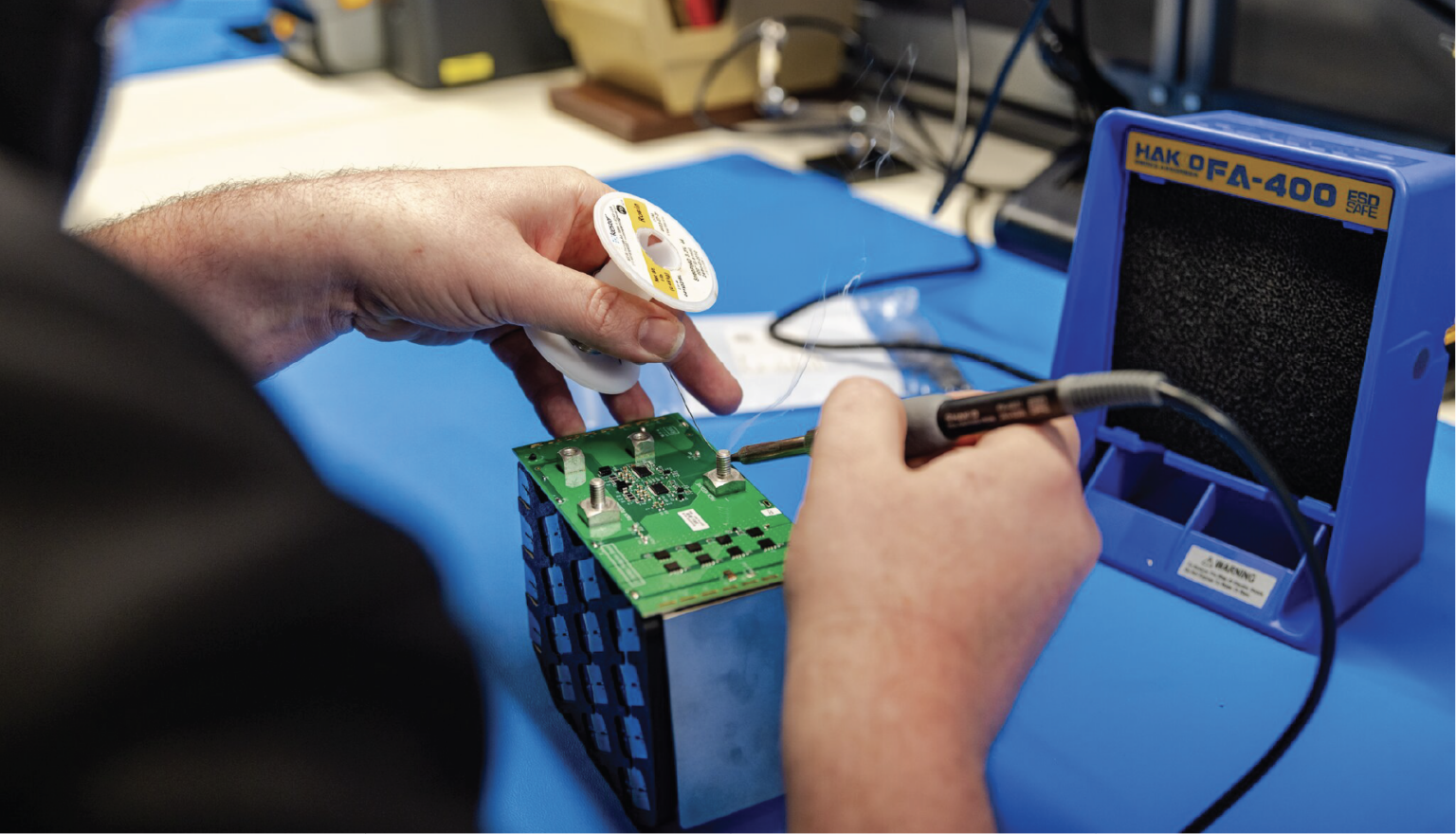

No matter how advanced modeling tools become, there is no substitute for testing a physical battery pack in real-world conditions. CAD models and simulations can predict performance, but they cannot capture every variable, especially in harsh industrial or defense environments. A design that looks sound on paper may struggle with heat buildup, vibration, or unexpected load patterns once deployed. Prototyping closes that gap.

Why prototyping matters:

Best practices for real-world validation:

Action: Budget for at least two rounds of physical prototyping, even if timelines are tight. The first round should focus on proving the basic design under real conditions. The second should refine details and validate compliance before moving to production. This step adds time up front, but it reduces the risk of catastrophic delays once a program is in the field.

By committing to rigorous prototyping, organizations move beyond theoretical performance. They gain confidence that the battery pack will function safely and reliably when the stakes are highest.

Even the best-designed battery pack can stall a program if the development cycle drags on. Industrial and defense organizations are under pressure to launch faster, respond to shifting requirements, and adapt to unpredictable supply chain realities. The right partner can make the difference between a program that meets its mission timeline and one that falls behind.

What to look for in a partner:

Action: When evaluating partners, consider speed and adaptability as much as technical capability. Ask questions such as:

Choosing a partner who understands both the technical requirements and the realities of program schedules ensures that battery pack development does not become the bottleneck. Instead, it becomes a competitive advantage, enabling faster deployment with fewer risks.

By prioritizing speed, flexibility, and secure supply, organizations can align battery development with mission timelines and avoid the delays that often derail industrial and defense programs.

Choosing the right battery pack for industrial and defense applications is not a matter of picking cells from a catalog. It requires a structured process that begins with a clear mission profile, translates that mission into precise power requirements, addresses risks before they cause delays, validates performance through real-world prototyping, and leverages a partner who can move at program speed.

Organizations that follow this approach gain more than a reliable power source. They reduce program risk, shorten development cycles, and ensure that their systems perform consistently in the environments where it matters most. For industrial operators, that means vehicles and equipment that stay productive and profitable. For defense programs, it means mission readiness and dependable performance in unpredictable conditions.

At Re:Build Battery Solutions, we specialize in turning this process into reality. Our team combines deep expertise in pack design, BMS development, and modular platforms with U.S.-based engineering and manufacturing. The result is a complete battery solution that is tailored to your mission, tested for real-world performance, and delivered on the timelines modern programs demand.

The right battery pack is more than a component. It is a foundation for operational success. By taking a disciplined approach and partnering with a team that understands the stakes, organizations can transform battery selection from a potential weak point into a true competitive advantage.

Fill out the form below and someone from the Re:Build Battery Solutions team will be in touch with you shortly.

Looking to connect with an experienced team?

Look no further than Re:Build Battery Solutions! We are excited to connect with you.