Re:Build Battery Solutions, a Re:Build Manufacturing member company, provides end-to-end battery services, spanning product design, development, volume production, and factory construction. We partner with U.S.-based companies to deliver high-quality, cost-effective battery engineering and manufacturing solutions, helping them maintain a competitive edge in the global market. Whether you require a turnkey partner or specialized support to enhance your in-house battery capabilities, we customize our expertise to align with your specific goals. As a pioneer in U.S. industrial innovation, Re:Build Battery Solutions combines cutting-edge technology with strategic insights to drive measurable, lasting success.

The Re:Build Battery Solutions team draws on extensive experience from the world’s leading battery companies, including Panasonic, Envision AESC, A123, Nissan, General Motors, NEC and Rogers Corporation, to deliver unmatched expertise in battery technology. We specialize in designing, developing, producing, and testing battery packs and battery management systems at scale, while also building and operating advanced battery manufacturing assembly lines. Our proven track record in engineering, product development, manufacturing, and operations reflects our commitment to providing innovative, high-performance battery solutions that meet the most demanding industry standards.

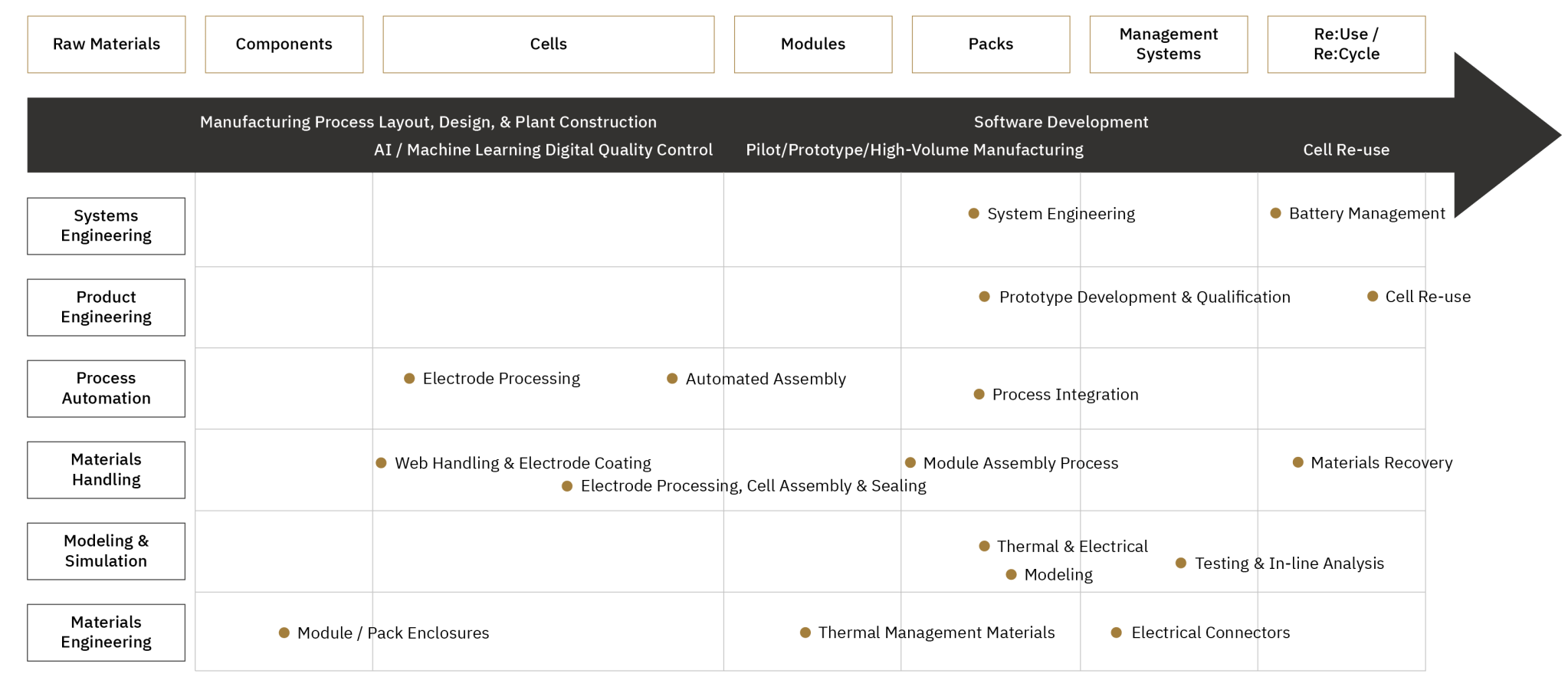

Re:Build Battery Solutions delivers comprehensive expertise across the entire battery value chain, from product innovation and industrial automation to component and systems production. Our integrated capabilities ensure that U.S.-based battery manufacturing is not only competitive but also high-quality and cost-effective at every stage of development and production.

Our state-of-the-art facilities in New Kensington, PA, are designed to support every stage of battery development, from early concept prototypes to quick-response manufacturing, low-rate initial production, and high-volume manufacturing. Spanning 175,000 square feet—with capacity to expand to 750,000 square feet—our facility is equipped to meet the demands of even the most complex projects. Key features include laser welding and wire bonding equipment, a 65-ton crane, rail access, and 15MW of available power, ensuring we can handle a wide range of production needs. Certified to the highest industry standards, including AS9100, and ITAR compliance, we deliver quality and reliability you can trust.

Our prototype development facility offers a versatile and collaborative space where ideas take shape and products come to life. Designed to support comprehensive development programs, it enables the assembly and testing of critical systems, including battery management systems (BMS), electronics, thermal management systems, and structural components. Equipped with advanced tools such as laser welding and wire bonding, our facility accommodates cells of all chemistries and form factors, ensuring adaptability to your unique project needs.

Re:Build Battery Solutions’ production site features cutting-edge module and pack manufacturing processes designed to meet the evolving demands of today’s competitive market. By leveraging advanced, data-driven process monitoring, we deliver real-time quality control, ensuring seamless progression from low-rate initial production to high-volume manufacturing. Our approach guarantees the quality, yield, and efficiencies your products need to stand out.

Throughout the manufacturing process, we collect multimodal data from electrical testers, infrared cameras, and physical inspection stations. This integrated system creates a comprehensive digital thread for every battery cell, module, and pack, enabling traceability, precision, and continuous improvement.

At Re:Build Battery Solutions, we combine battery development and production expertise with digital innovation, custom software development, and Lean methodologies to deliver transformative results for our clients. By combining cutting-edge technology with a focus on operational excellence, we create customer-focused solutions that streamline processes, unlock growth opportunities, and drive measurable impact. Our commitment to understanding your unique needs ensures that every solution is tailored to deliver meaningful change and lasting value.

Re:Build Battery Solutions stands apart in the market through our unparalleled vertical integration, combining a diverse range of capabilities, skillsets, and expertise under one roof. From advanced engineering and custom manufacturing to strategic sourcing and end-to-end product lifecycle support, our integrated approach eliminates inefficiencies, accelerates innovation, and ensures exceptional quality. This seamless synergy empowers us to deliver unmatched value and adaptability, giving our customers a strategic edge in a competitive landscape.

The Test Kitchen is our dedicated prototyping and development lab, designed to streamline the creation and testing of custom lithium-ion battery packs. This cutting-edge facility enables us to quickly produce and refine prototypes while optimizing manufacturing processes, giving our customers a faster path to market and superior product quality.

We leverage advanced digital tools to enhance every stage of the battery development and manufacturing process. From real-time production monitoring to predictive analytics for battery performance, our digital systems ensure precision, efficiency, and scalability. By integrating data-driven insights into manufacturing workflows, we enable optimized throughput, reduced downtime, and a seamless transition from prototyping to full-scale production.

Our custom software solutions are designed to address the unique challenges of battery engineering and production. From advanced battery management system (BMS) algorithms to proprietary tools for optimizing cell performance, our software streamlines development, enhances operational control, and ensures compliance with industry standards. Whether you need tailored diagnostics, energy storage analytics, or automation controls, we deliver software solutions that drive innovation and efficiency.

By applying Lean principles to battery manufacturing, we eliminate inefficiencies in production processes while enhancing yield and quality. From minimizing material waste during electrode coating to streamlining battery assembly workflows, our Lean-driven approach ensures faster production cycles, reduced costs, and superior product performance. Our proven methodologies empower you to scale operations while maintaining the highest standards of safety and reliability.

Looking to connect with an experienced team?

Look no further than Re:Build Battery Solutions! We are excited to connect with you.