Re:Build Battery Solutions provides end-to-end expertise in battery systems and production automation. We engineer battery modules, packs, and BMS hardware/software, and build the automation systems that make high-volume production possible. Our vertical integration shortens lead times, lowers costs, and ensures full U.S.-based traceability across the product lifecycle.

We partner with customers across the battery industry to turn complex challenges into reliable solutions. From advanced pack development to scalable production lines, our expertise in design, engineering, and manufacturing helps optimize performance, improve efficiency, and ensure dependable results at every stage of a project.

We design and engineer high-performance lithium-ion packs that deliver reliable power in the most demanding applications. With advanced cooling, rugged enclosures, and integrated safety systems, our packs are built for long life, consistent performance, and mission-critical reliability.

Our BMS platforms give customers complete control over battery performance and safety. Whether custom-designed or ready-to-deploy, our systems provide accurate monitoring, fault detection, and secure operation across mobile and stationary applications, enabling longer life, better performance, and lower risk.

From prototypes to high-volume runs, we deliver scalable, U.S.-based manufacturing with full digital traceability. Using modern assembly techniques and rigorous quality testing, our teams ensure consistent results, lower risk of failure, and faster time-to-market at every stage of production.

We engineer and commission custom assembly lines that help customers scale production efficiently and reliably. By integrating automation, quality testing, and lean process design, our solutions improve throughput, enhance operator efficiency, and grow with your business.

Federal incentives are transforming the economics of domestic battery production, but only for those who can navigate the complexity. This in-depth industry report decodes the One Big Beautiful Bill Act (OBBBA), offering battery manufacturers, integrators, and supply chain partners a clear guide to the new rules, risks, and rewards.

Explore what the latest legislation means for 45X and 48E tax credits, critical mineral incentives, Prohibited Foreign Entity (PFE) restrictions, and Material Assistance Cost Ratio (MACR) compliance. Learn how leading battery companies are aligning with defense priorities, securing funding, and building resilient, U.S.-based supply chains.

At Re:Build Battery Solutions, our expertise helps customers overcome their toughest battery challenges. We combine engineering excellence with advanced manufacturing practices to deliver high-quality, cost-effective solutions. Explore our featured case studies to see how our commitment to innovation and quality drives success across the battery industry.

Re:Build Battery Solutions delivered lightweight, high-performance battery packs for a leading defense contractor’s advanced drone program, meeting stringent performance, durability, and U.S. supply chain requirements within a tight six-month timeline.

Re:Build designed and implemented an automated lithium battery production and assembly system, optimizing materials handling, equipment integration, and process automation to increase productivity, scalability, and global competitiveness for a leading battery manufacturer.

Re:Build Battery Solutions implemented an Industry 4.0 automated battery cell test station, integrating robotics, visual inspection, and real-time data processing, reducing inspection time by 80%, cutting battery pack assembly time nearly in half, and eliminating manual data entry errors.

The customer was developing a new grid-scale flow battery and was looking for a low cost, custom, stack health monitor. The available commercial products contained features and functions that were not required as well as other aspects that would have added unnecessary cost into the product.

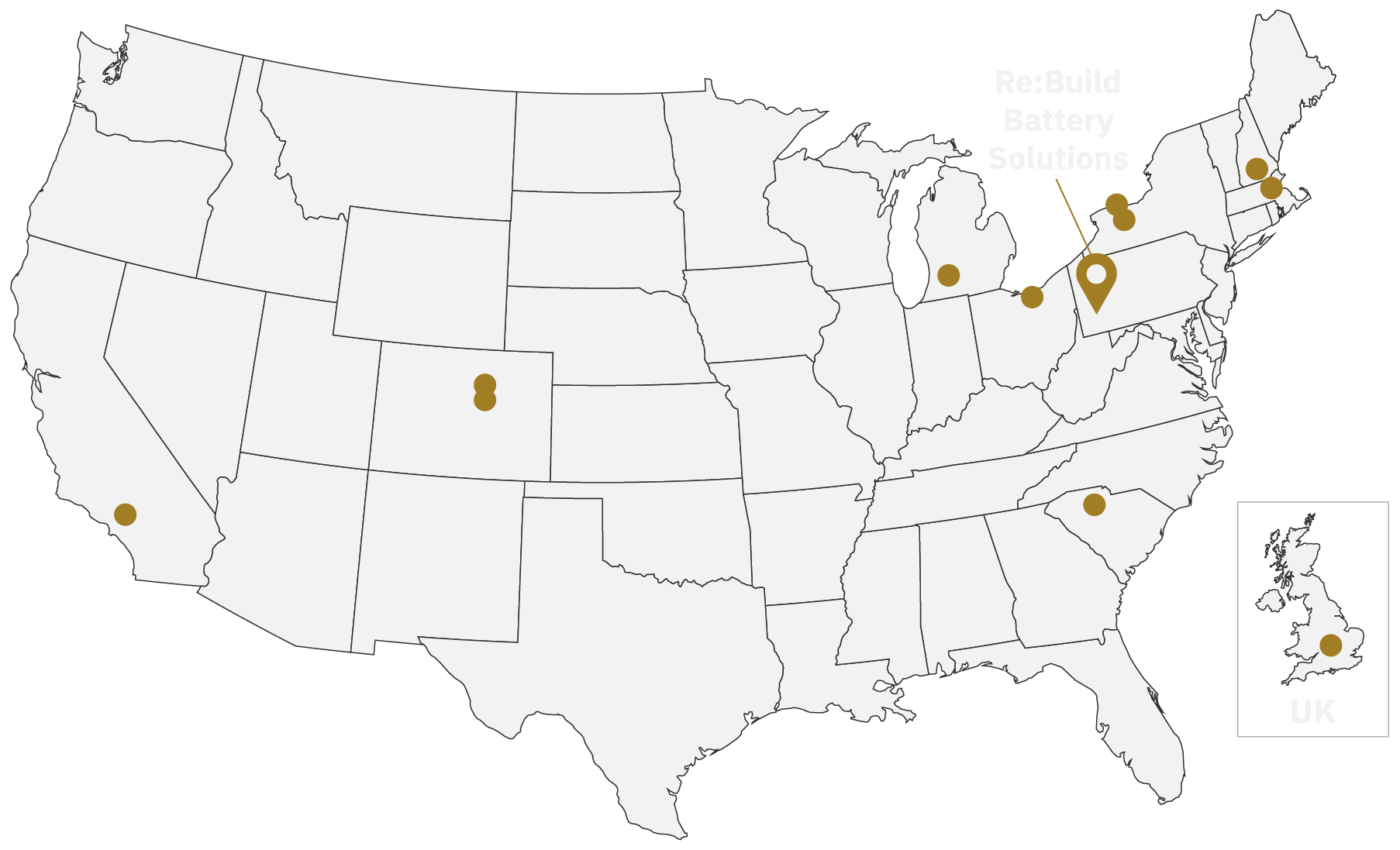

Across the United States, Re:Build Manufacturing is growing a family of engineering and manufacturing businesses whose combined experience creates an industrial powerhouse that is greater than the sum of its parts. Our expertise in operations management, product manufacturing, technical and engineering proficiency, and product lifecycle management is changing the way industrial America does business. Close collaboration yields more value for the good of all–our customers, our employees, and the community–for the very long term.

As part of Re:Build Manufacturing’s network of Member Companies, we have added to our capabilities to generate even more value for our customers. We can now do more than ever across a wider variety of industries, all while serving customers from start-ups to large scale.

With a team over 400 engineers across the country, we ensure seamless collaboration and support for our clients, wherever they are located.

Looking to connect with an experienced team?

Look no further than Re:Build Battery Solutions! We are excited to connect with you.