Re:Build Battery Solutions, a member of Re:Build Manufacturing, provides turnkey battery solutions spanning design, prototyping, manufacturing, and factory build-out. We partner with U.S.-based companies to deliver high-quality, cost-competitive battery packs, modules, and BMS systems while ensuring secure, domestic supply chains.

Our mission is simple: accelerate innovation in energy storage while strengthening North American manufacturing. Whether you need a custom pack, a ready-to-deploy BMS, or a full-scale production line, we deliver the expertise and infrastructure to make it happen.

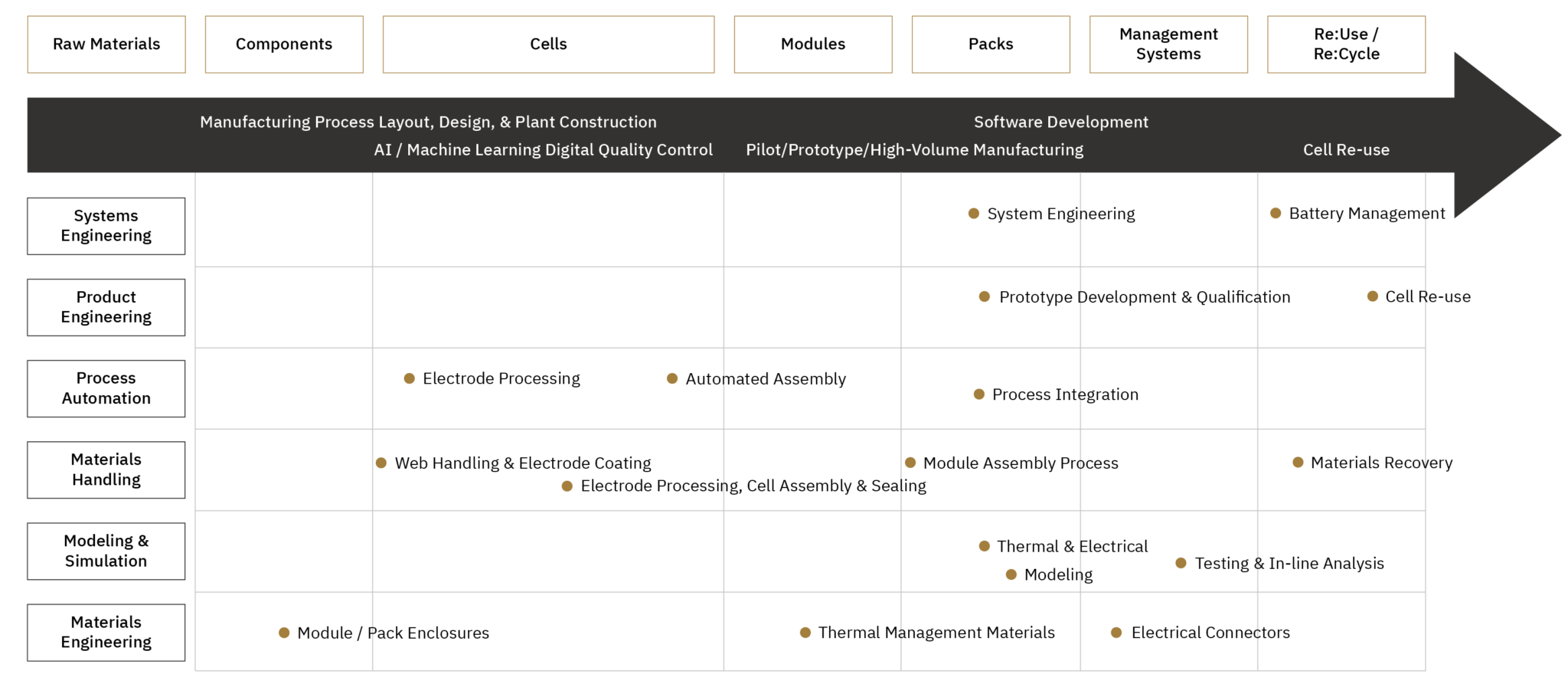

Re:Build Battery Solutions delivers comprehensive expertise across the entire battery value chain, from product innovation and industrial automation to component and systems production. Our integrated capabilities ensure that U.S.-based battery manufacturing is not only competitive but also high-quality and cost-effective at every stage of development and production.

Our state-of-the-art facilities in New Kensington, PA, are designed to support every stage of battery development, from early concept prototypes to quick-response manufacturing, low-rate initial production, and high-volume manufacturing. Spanning 175,000 square feet, with capacity to expand to 750,000 square feet, our facility is equipped to meet the demands of even the most complex projects. Key features include laser welding and wire bonding equipment, a 65-ton crane, rail access, and 15MW of available power, ensuring we can handle a wide range of production needs. Certified to the highest industry standards, including AS9100, and ITAR compliance, we deliver quality and reliability you can trust.

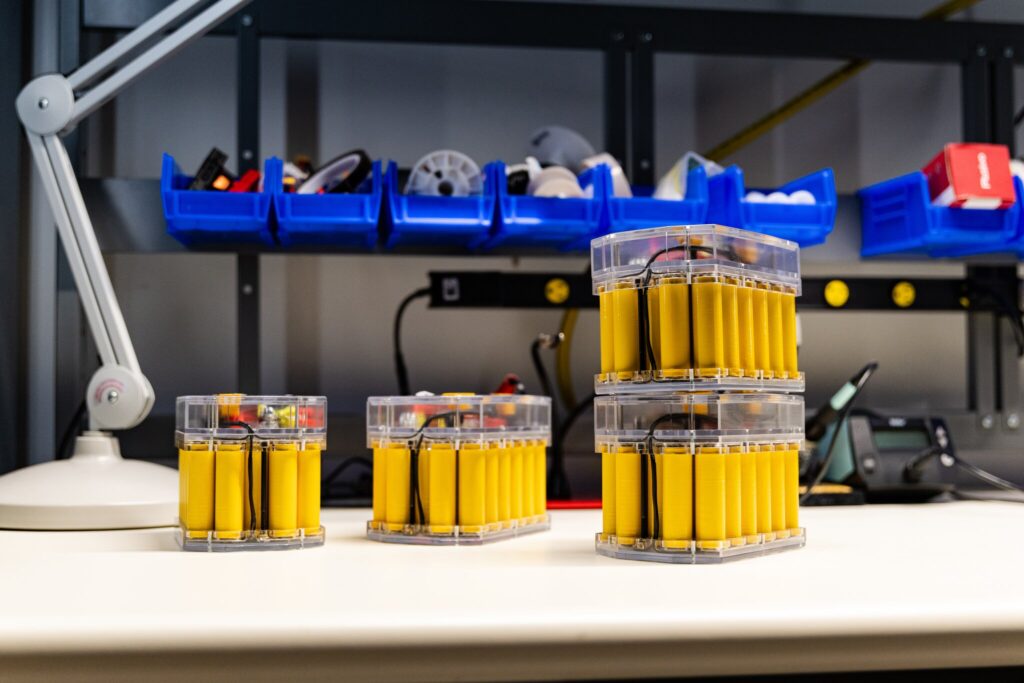

Our prototype development facility is where concepts quickly turn into proven designs. Purpose-built for collaboration and rapid iteration, it supports the assembly and testing of battery management systems (BMS), electronics, thermal management, and structural components. Equipped with advanced tools including laser welding and wire bonding, the lab accommodates all major cell chemistries and form factors, ensuring flexibility for any program.

By combining engineering expertise with hands-on prototyping, we help customers de-risk designs, validate performance early, and move efficiently toward production.

Our production facility in New Kensington, PA delivers high-quality, U.S.-based battery manufacturing at scale. Designed for both pilot programs and high-volume output, it features advanced processes for module and pack assembly backed by real-time, data-driven quality control.

Throughout production, we capture multimodal data from testers, infrared cameras, and inspection stations, creating a comprehensive digital thread for every cell, module, and pack. This traceability ensures consistent quality, regulatory compliance, and continuous improvement, giving customers the confidence that every product leaving our facility meets the highest standards of safety, reliability, and performance.

At Re:Build Battery Solutions, we deliver more than batteries, we deliver speed, reliability, and confidence. By combining deep engineering expertise with advanced digital tools, lean manufacturing, and U.S.-based production, we help customers reduce risk, accelerate timelines, and achieve long-term success.

We bring design, engineering, manufacturing, and factory build capabilities together, eliminating handoffs and inefficiencies. This seamless approach accelerates innovation, ensures quality, and gives our customers a competitive edge.

We bring design, engineering, manufacturing, and factory build capabilities together, eliminating handoffs and inefficiencies. This seamless approach accelerates innovation, ensures quality, and gives our customers a competitive edge.

We integrate real-time monitoring, predictive analytics, and full digital traceability into every project. This ensures consistent quality, minimizes downtime, and makes scaling from pilot to gigafactory efficient and reliable.

From advanced BMS algorithms to proprietary diagnostic tools, our software platforms optimize battery performance and compliance. Customers gain tailored solutions designed for their exact application requirements.

We apply lean principles to maximize yield, reduce costs, and eliminate waste. The result is faster production cycles, higher reliability, and scalable systems that meet the highest safety standards.

Looking to connect with an experienced team?

Look no further than Re:Build Battery Solutions! We are excited to connect with you.